Resin

Project Description:

Get inspired with ways to use UV resin on Grafix Plastic!

Designed by: Celia Buchanan

Difficulty: Easy

Materials:

Steps to Make This:

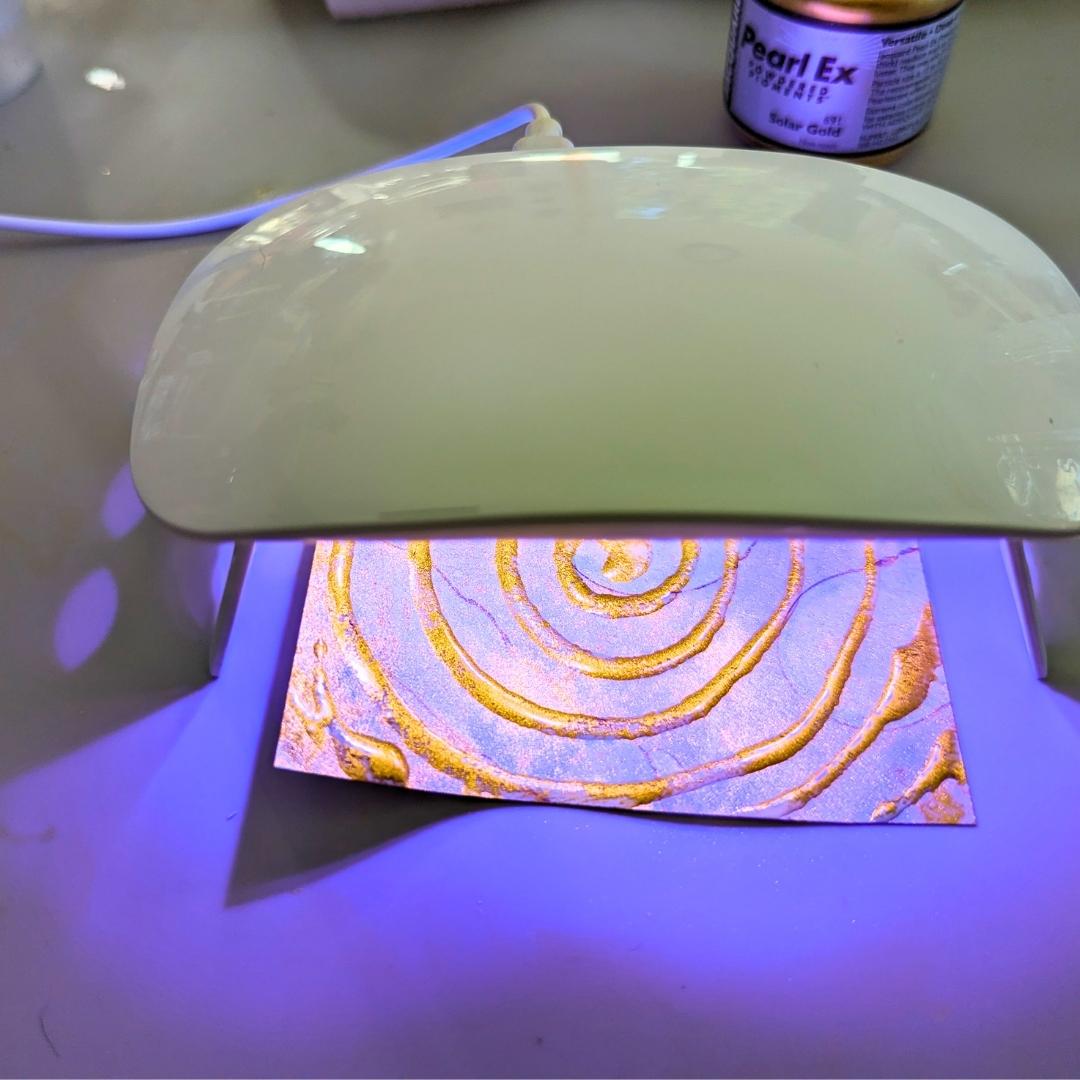

White Craft Plastic & UV Resin:

The Craft Plastic was patterned using diluted alcohol inks with isopropyl 91%. Once thoroughly dry a spiral bead of UV resin was applied to the surface.

While the UV resin was still wet mica pigment was sprinkled onto the surface. Don’t worry about mica going onto areas that don’t have resin on them. You will be able to dust that off once the resin is cured.

Place the piece under the UV lamp. In this case a small lamp was used and the piece was exposed for 30 to 60 seconds. The film was not affected by the heat of the lamp. It remained flat and did not curl. The resin had good adhesion to the film. Though, it is not recommended for use in high traffic areas or for items that will be handled a lot.

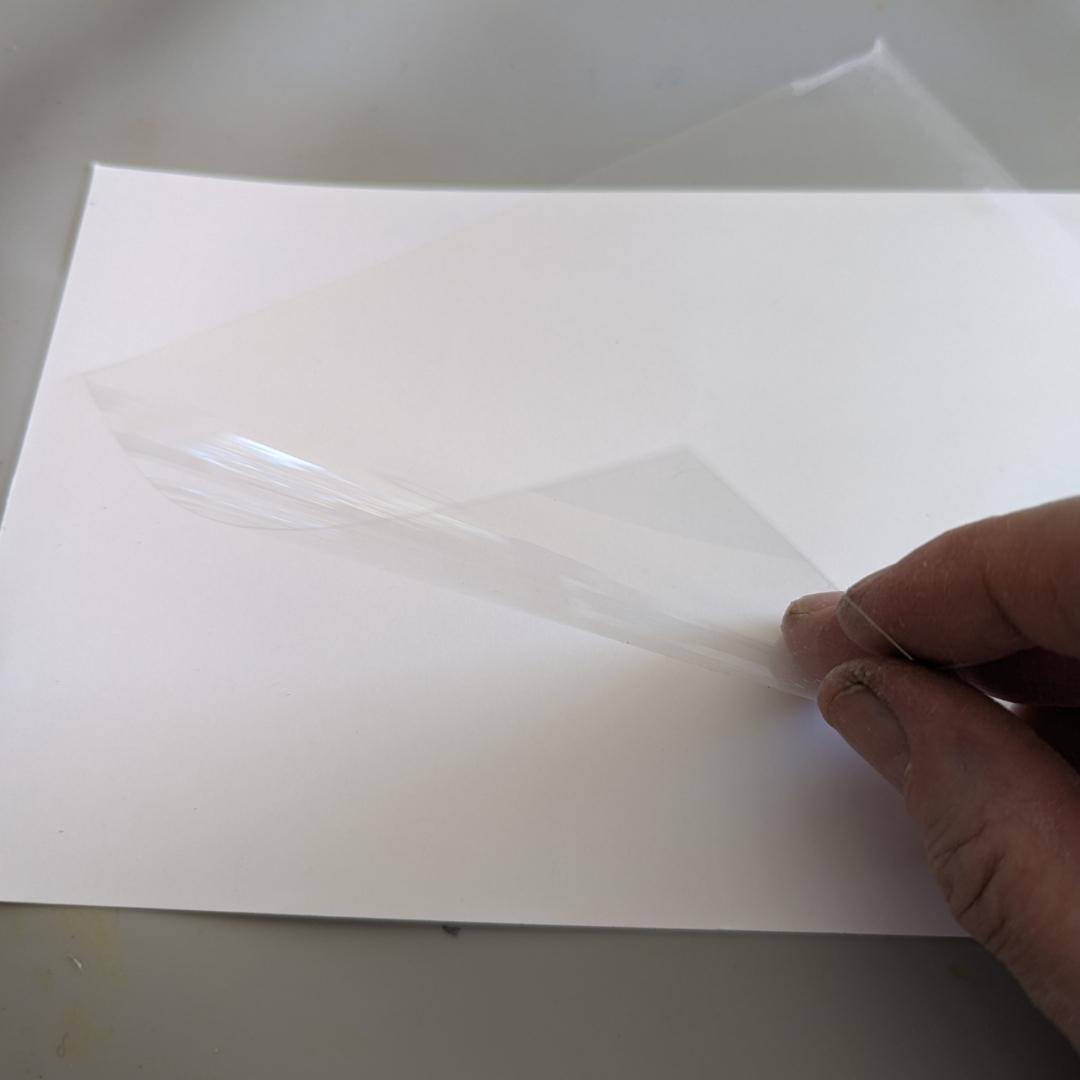

Dura-Lar Wet Media Film & UV Resin Skin

Dura-Lar Wet Media Film is particularly effective at releasing cured resin skins.

A spiral bead of UV resin was applied to the surface of the film and then it was cured under the UV light for approximately 30 seconds. Do a test first as UV lights vary in intensity and heat distribution from brand to brand.

After the first layer was cured a second bead was applied on top of the first spiral layer and the piece was cured again for 30 seconds. UV resin is best applied in several thin layers to aid with uniform hardening.

The film was not affected by the heat of the lamp. It remained flat and did not curl. The resin detached easily from the film in one piece.

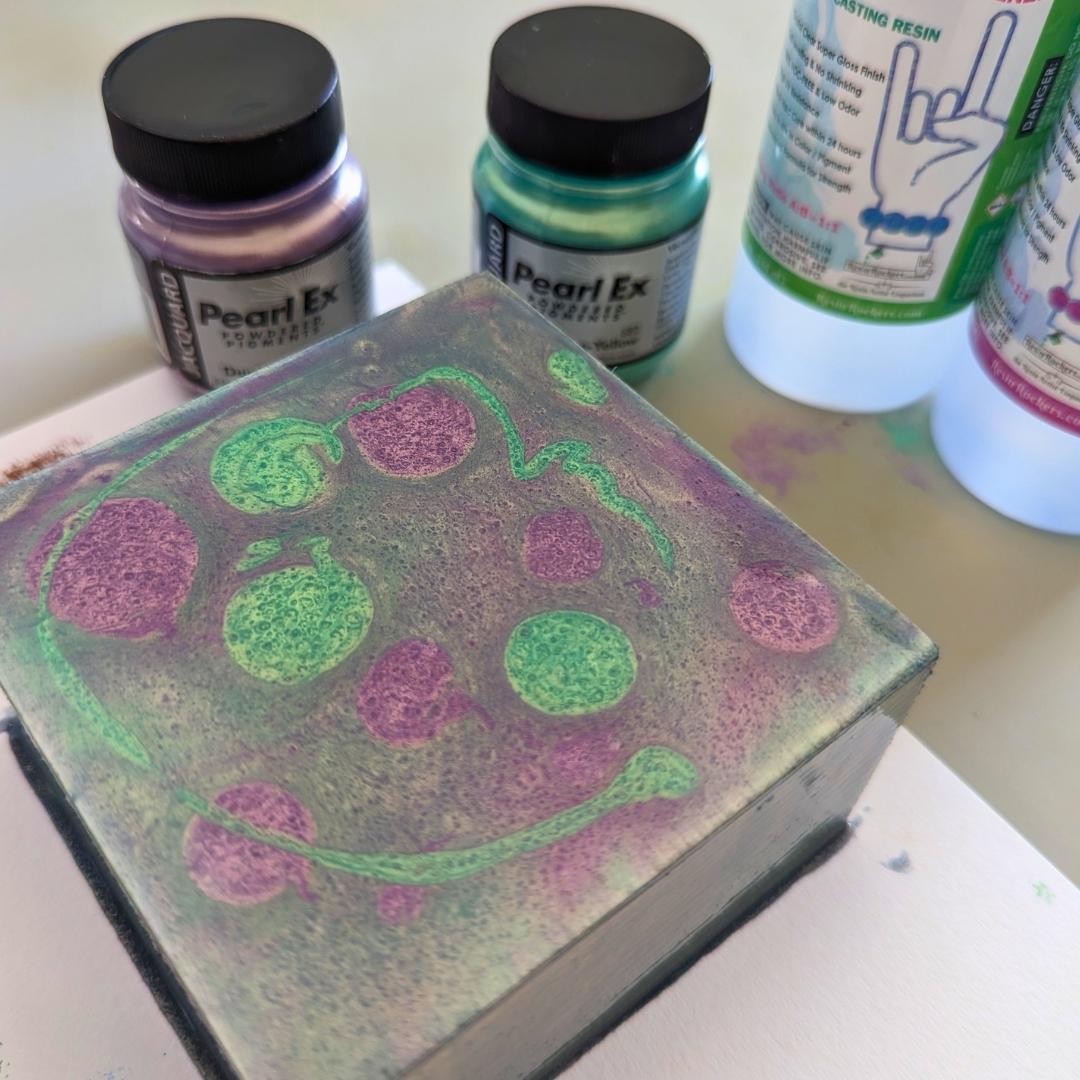

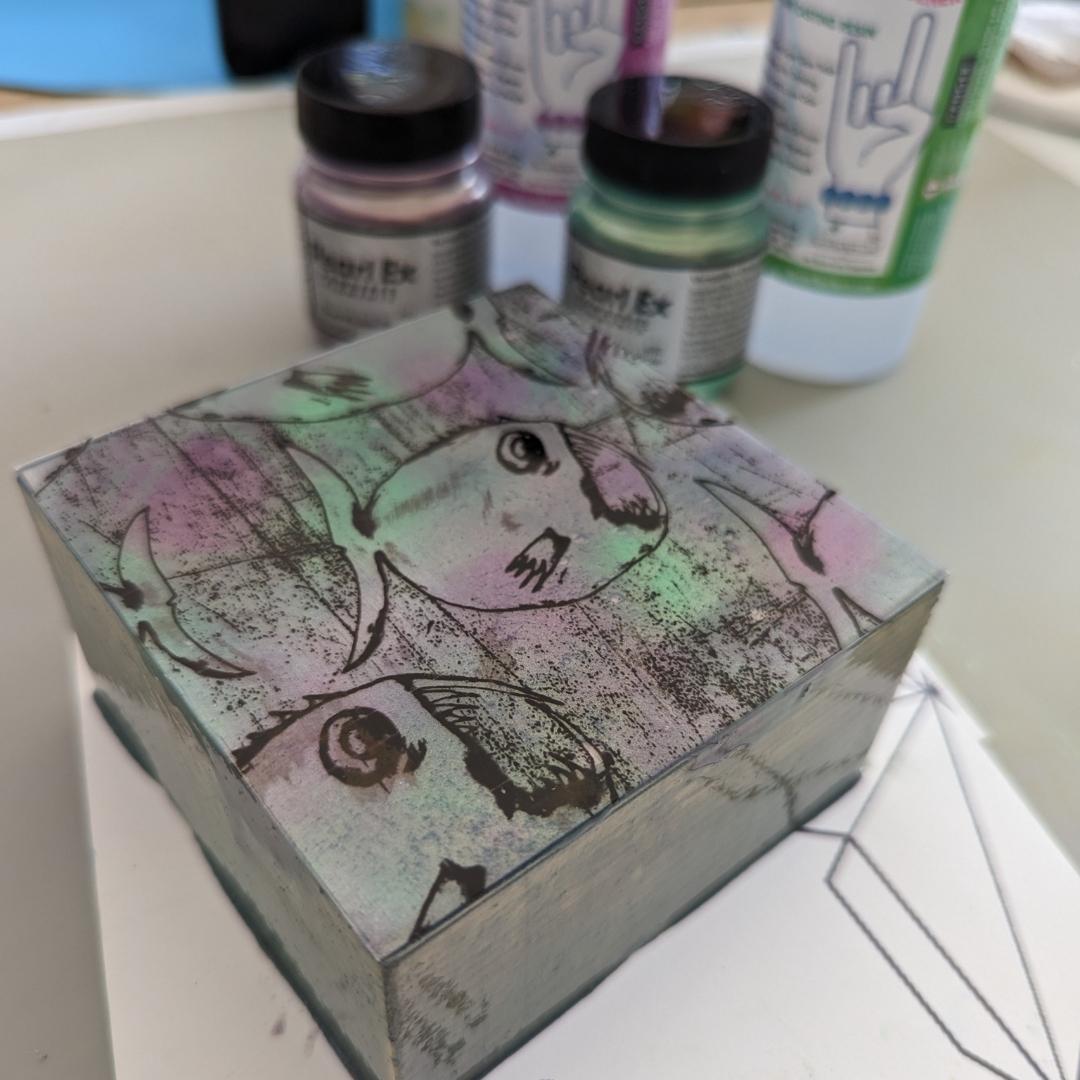

Clear Computer Grafix Film for Inkjet 8.5×11” and 11×17″ (non-adhesive backing) & two-part epoxy resin

A print was made using the CCG film through a standard inkjet printer. This was cut to size 4” x 4”

The epoxy was a 1:1 ratio of resin to hardener. Once thoroughly mixed it was divided into 2 containers. Two separate colors of mica pigment were mixed into each container.

The resin and mica mix was randomly applied to the surface and sides of a 4” x 4” x 2” birch wooden panel.

While the resin is still in a fluid state, position the clear printed Computer Grafix film on top of the resin coated panel. Mix up a second batch of epoxy resin and evenly coat over the top on the film to encase the image within the clear resin, providing a durable glossy finish.

No reaction to the resin was observed. The film lay flat and did not curl. Note all resin will yellow over time. However, some higher quality resins will yellow at a slower rate.

[/efsrow]